ScanCrete Solution

Couldn't load pickup availability

ScanCrete is a solution from Leica Geosystems that optimises sprayed concrete (shotcrete) application by empowering users to spray, capture and compare. This end-to-end solution improves data capture efficiency, minimises waste and streamlines productivity, consequently reducing exposure time in hazardous environments. Users can conduct easy-to-understand visual reporting on-site or in the office through industry-proven technology for accurate and real time as-built analysis.

KEY BENEFITS

End-to-end workflow from field to office provided exclusively by Leica Geosystems

Perform real time layer thickness analysis of structures using intelligent sensors and software that work seamlessly together

Simplify as-built inspection of sprayed concrete layer-by-layer

Conduct as-built analysis and verification instantly in hazardous environments without revisits or delays

Save costs by ensuring there is minimal waste of materials and reduce the number of personnel required for the task

With the Leica RTC360 or Leica BLK360, users position a 3D laser scanner close to the area of interest for the tunnel surface and perform an initial scan. They then spray concrete and, after, perform and transmit a second scan to the Leica CS35 tablet computer running Captivate Inspect Layer application.

COMPARE

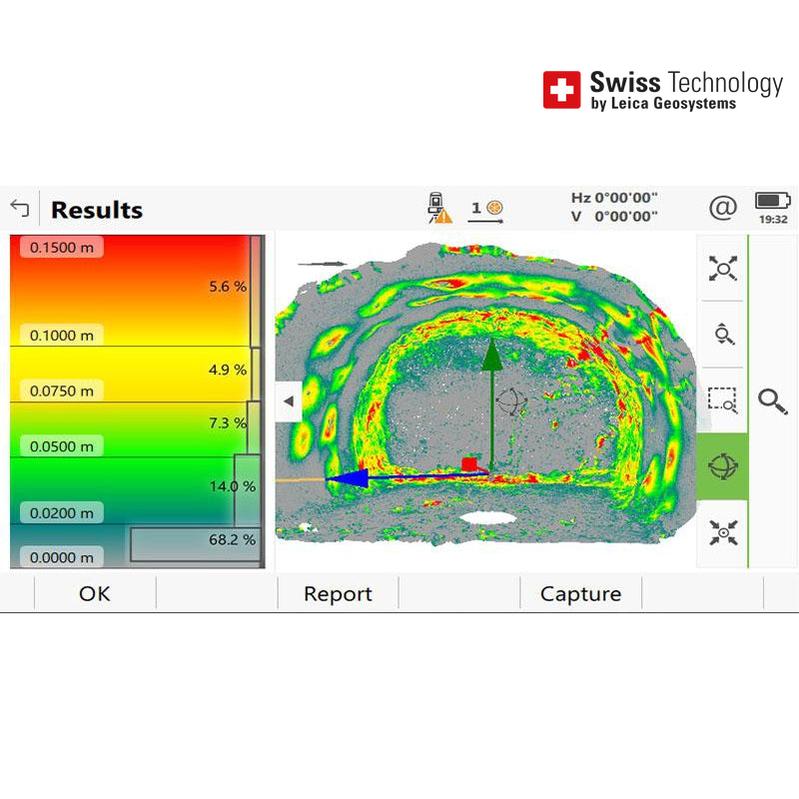

The Captivate Inspect Layer application compares two or more scans to identify the thickness between the layers or surfaces. If the instrument’s position and orientation is changed between scan setups, the app automatically adjusts by aligning the scans. This feature delivers real time results visually, simply and efficiently. The scanned surfaces are compared within the app to visually identify too much or too little sprayed concrete compared to the desired layer thickness requirement.

OPTIMISE

With in-field real time validation of layer thickness, instant corrective actions can be taken without disrupting the workflow. Real-time data at the worksite also minimises 3rd party validation delays. Additionally, users can download the captured data via Wi-Fi or USB from the CS35 tablet computer for construction site records and performance reviews, then perform further analysis in the office with Leica Cyclone 3DR to transform their captured data into accurate and meaningful results.

SPRAY

Sprayed concrete (shotcrete) application is an essential task during conventional tunnel excavation. The entire area of sprayed concrete must be measured for layer thickness. If measurement results of the sprayed concrete layers are available in real time, concreting operations can achieve maximum efficiency without waiting for external validation. The visualisation of measurement results is fast and easy to understand, enabling better-informed decisions in the field.

Documents

Documents

$0.00 CAD